Diamond Journey: How Sarine is telling the story of diamonds

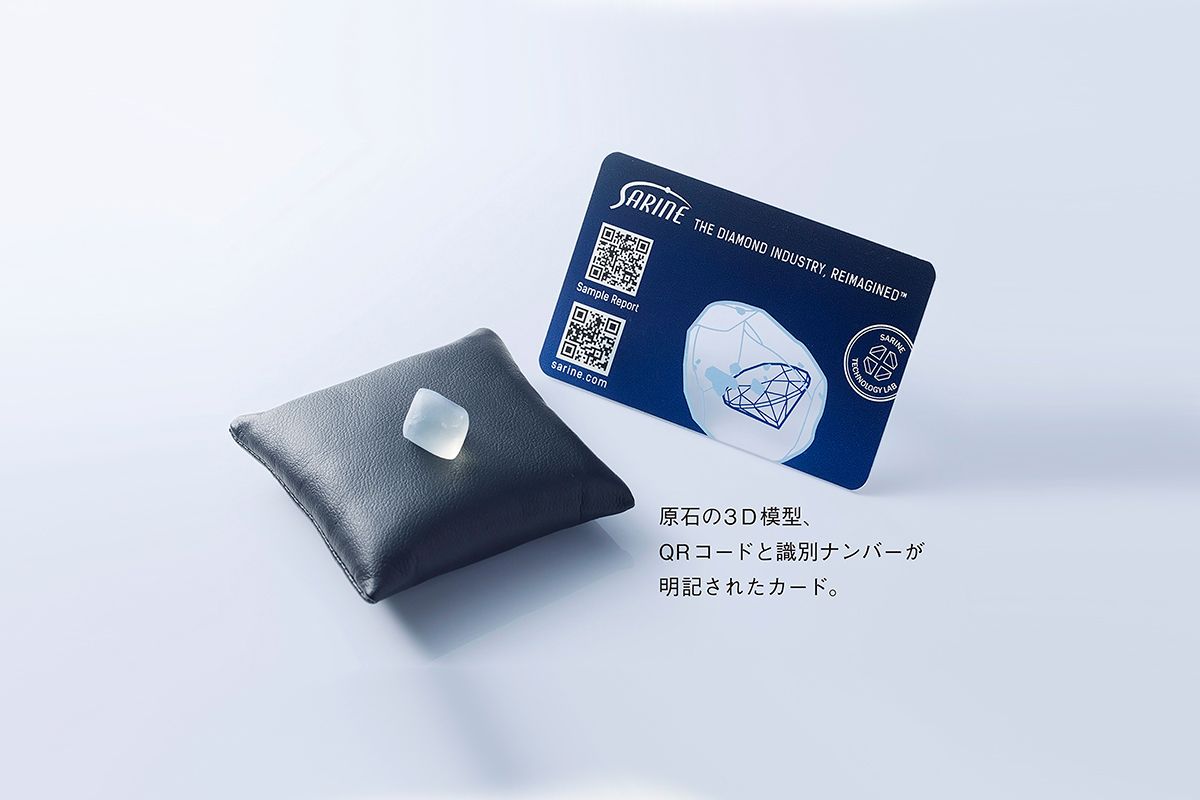

Imagine standing in a boutique on the Place Vendôme and holding a 3D model replica of the rough diamond from which a perfectly polished diamond, set within the piece you are about to purchase, was gleaned from. This is the new reality that Sarine is offering retailers and consumers with its cutting-edge technology, Diamond Journey™ – a process of tracing a diamond from mine to market and presenting the results in a digital format, similar to a biometric passport. I spoke to David Block, CEO of Sarine to found out more.

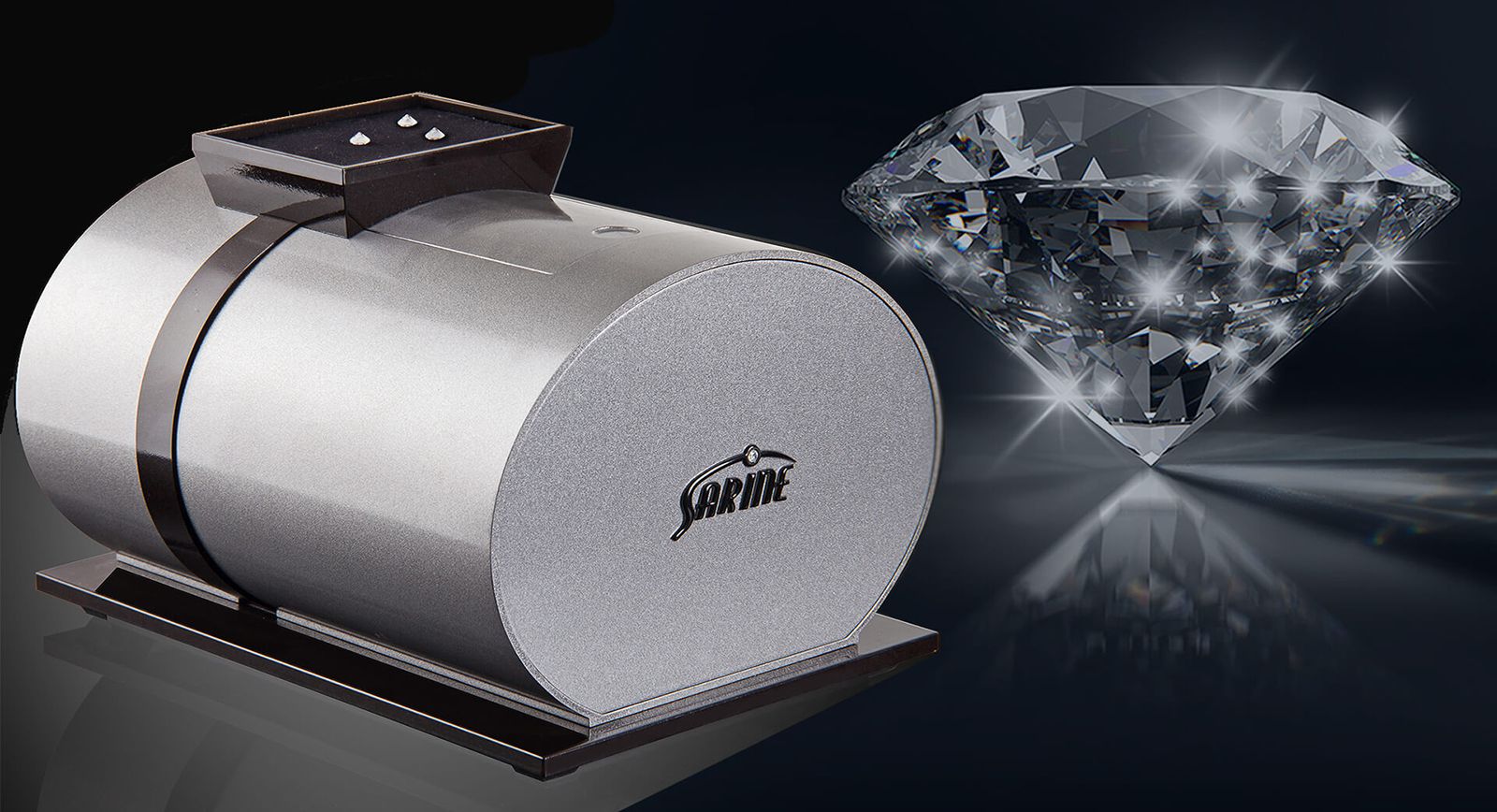

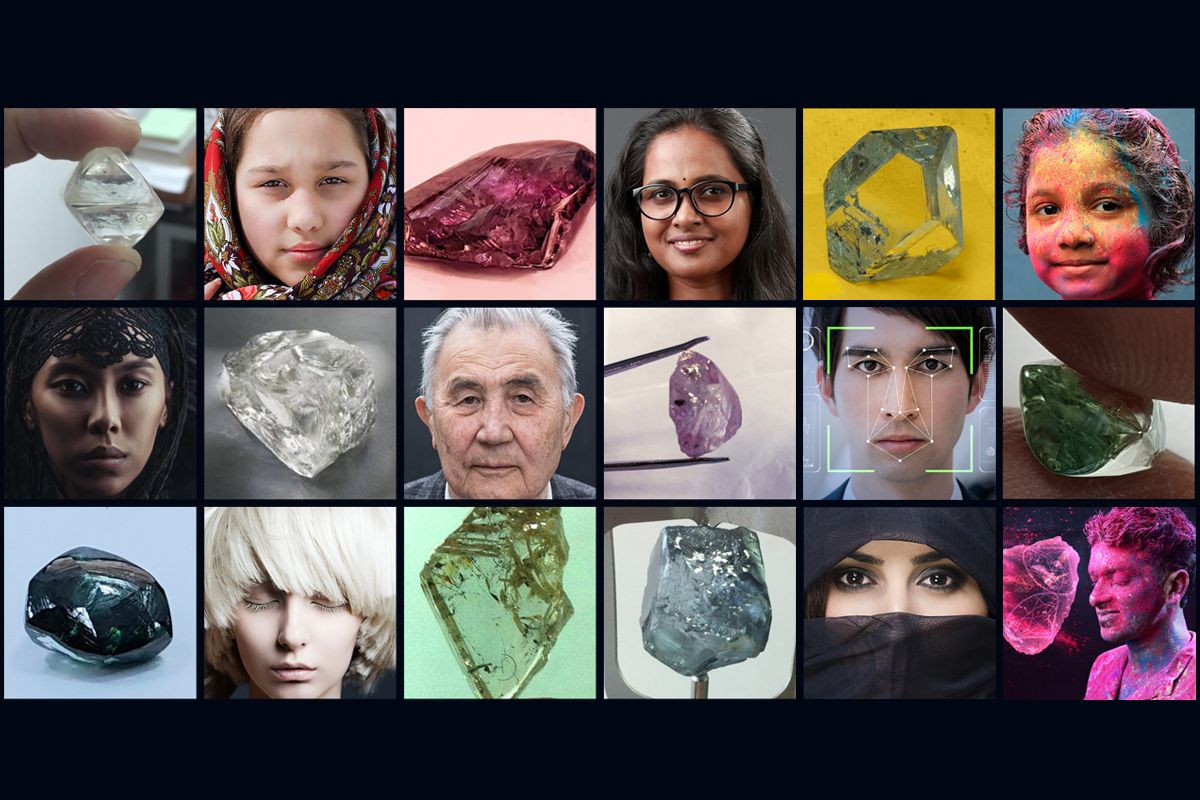

Just like a person, every diamond has a unique story to tell. That’s the poetic thinking behind Sarine’s ‘Diamond Journey™,’ which is a technically advanced, cloud-based process that tracks a diamond’s progress from its origin to its destination, culminating in a stunning digital report. Sarine is able to do this because its technology already exists in the diamond pipeline and is used worldwide by miners, manufacturers, cutters, polishers and every stage in between. This data has allowed Sarine to curate a process in which an individual stone can be traced along its route through the diamond industry and tell its own story, like a passport stamped with many different destinations.

Originating deep inside the earth, a diamond’s journey from mine to manufacturer, and finally, to jewellery store, is unique and fascinating. At every stage of diamond manufacturing – modelling, mapping, planning, cutting and polishing – Sarine’s advanced technologies are used to ensure the gemologist achieves the most valuable polished gem.

In reality, this gives jewellery lovers who wish to buy a diamond a complete story of their stone, its origin, the rough, the cutting process and the faceting process, which is presented to them in-store and/or via a digital report. During the sales process, retailers and brands can even show the customer an exact 3D replica of the original rough stone that their diamond was cut from! “Consumers today really want to understand where their products come from. Naturally diamonds and jewellery are no different, and the importance of understanding that journey from mine to the consumer is becoming increasingly important,” explains David.

The Sarine Diamond Journey focuses on the uniqueness of each diamond and its individual story from mine to market

The idea for the Sarine Diamond Journey™ evolved naturally in 2018 and was launched about 18-months ago. As you may know from previous articles, Sarine has been supplying technology to the diamond industry for over 30 years, so it is ideally placed to take this leap in traceability and transparency that’s designed with the end customer in mind. David continues: “You may not know it, but a large number of diamonds that end up on the market go through Sarine as part of the manufacturing process. We are tracking diamonds through this process so that customers can know where their diamond comes from, how it was manufactured and basically tell the story of that diamond journey.”

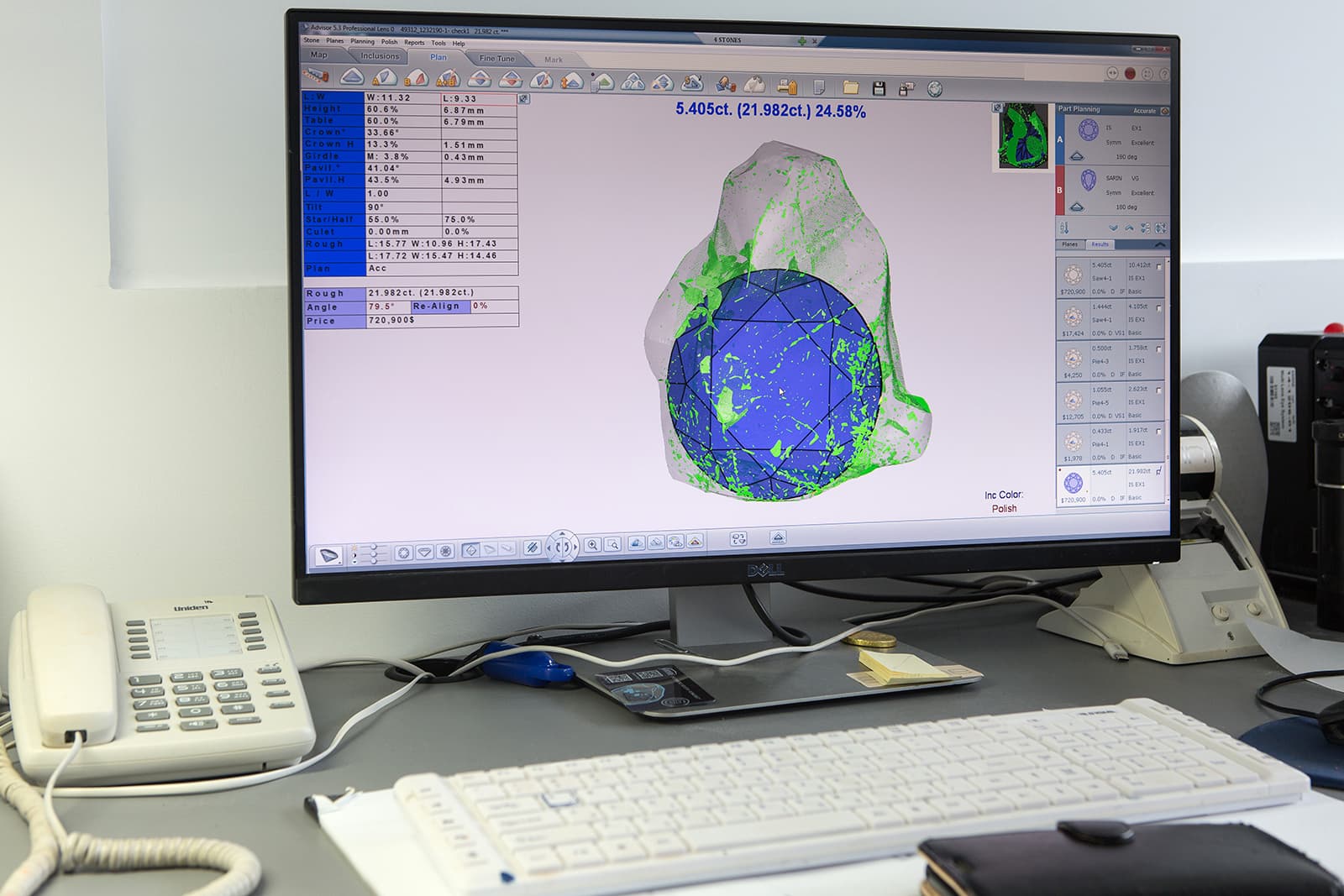

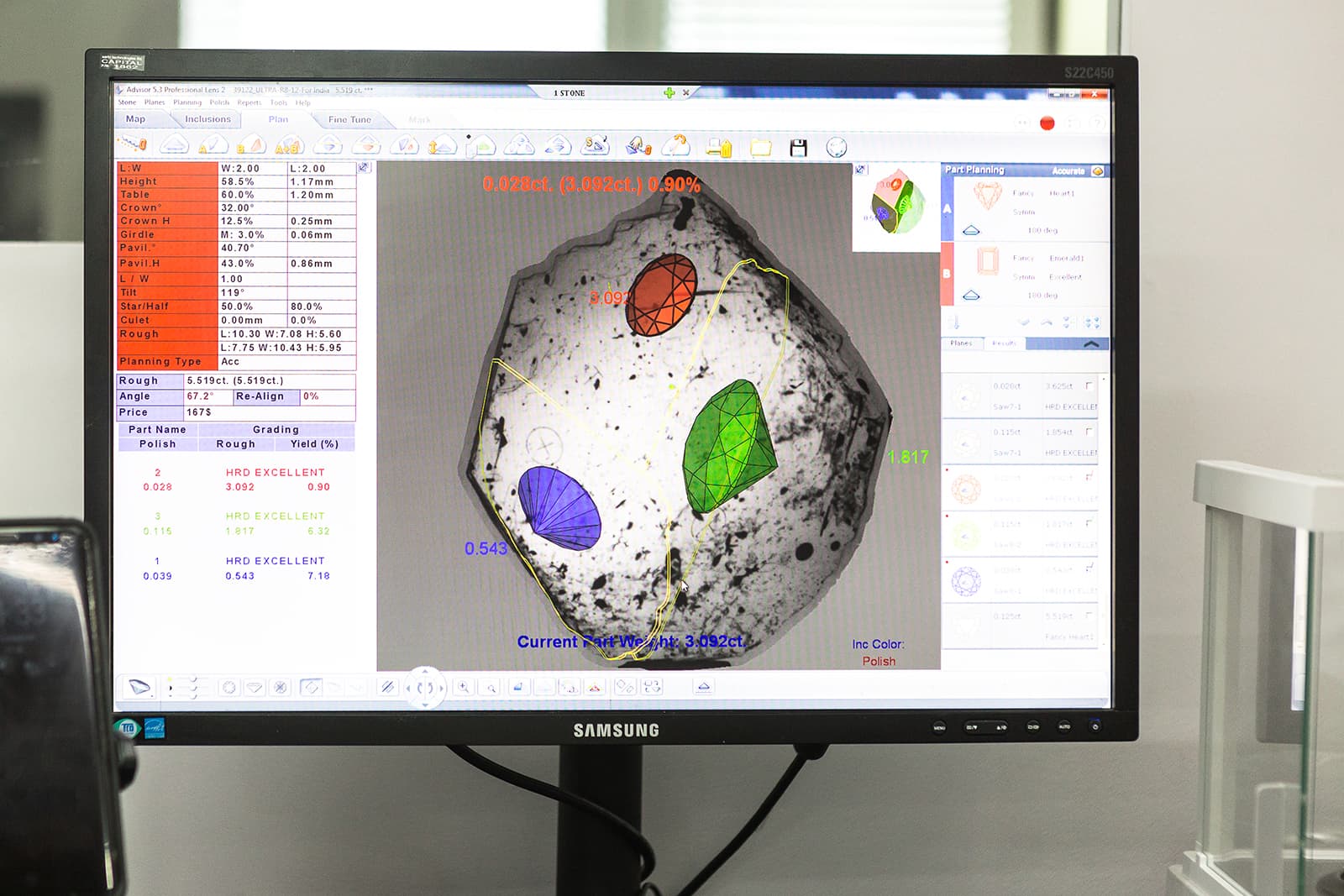

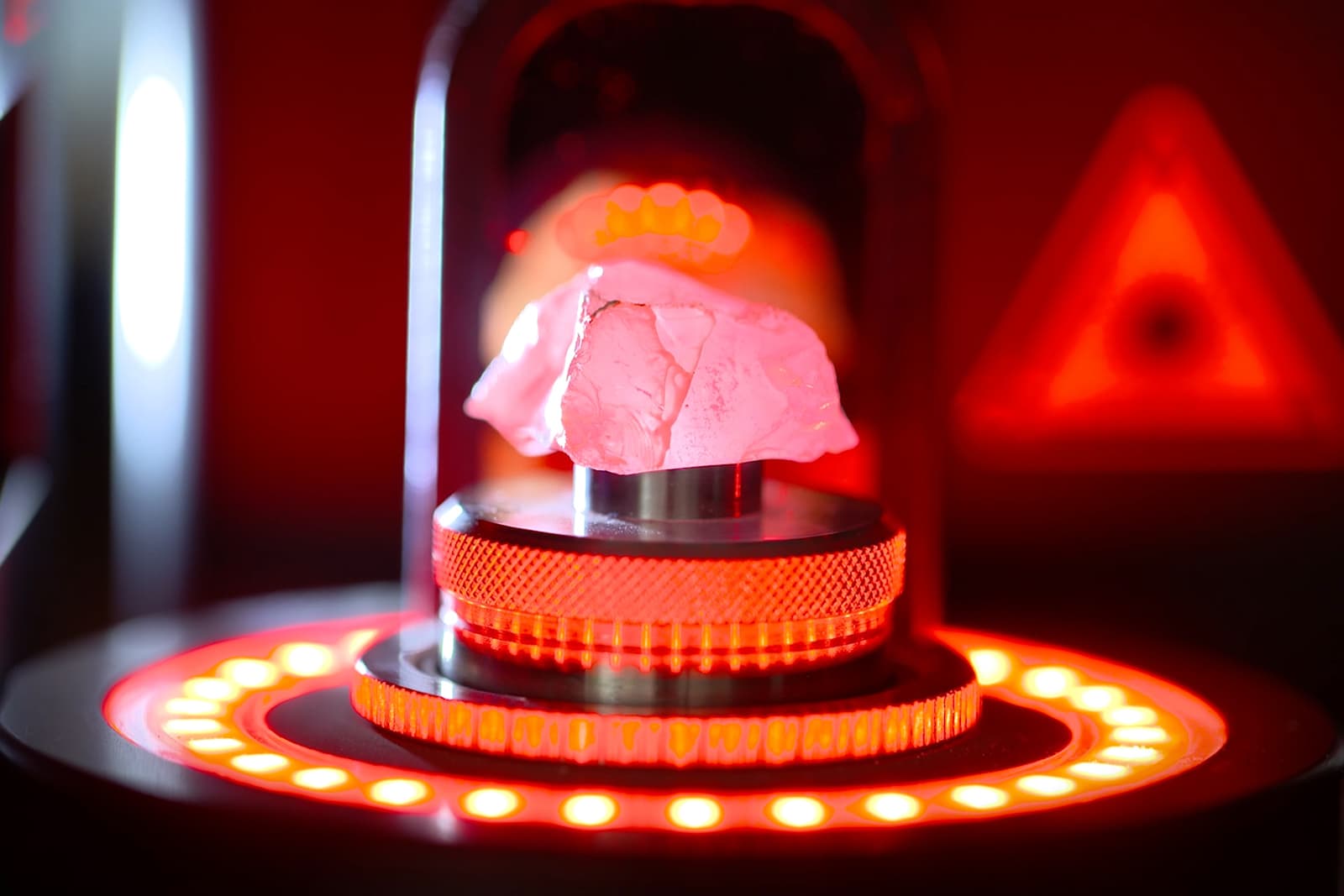

Sarine DiaExpert® technology maps a diamond’s external surface as part of the Sarine Diamond Journey

It’s easy to forget when looking at the latest high jewellery collections that manufacturing a rough diamond and turning it into a polished diamond is actually a long and complex journey. “We have a lot of technology along the pipeline that’s used for manufacturing, so we utilize the data that is created in this process to track a diamond step-by-step. It really highlights the fact that every rough diamond is unique and must be turned into a polished diamond in a unique way,” David explains.

The Sarine Diamond Journey gives customers the option of owning a 3D model of the original rough diamond from which their polished stone was cut

So, what are the stages a diamond goes through along its journey? Sarine Diamond Journey™ Traceability culminates all of that information into a Diamond Journey™ report that is a bit like a visual storybook. David describes it as giving buyers the chance to “reverse engineer” their polished stone, tracing each stage backwards to not only its country of origin but its mine of origin and entire journey as well. The first step is a 3D scanning procedure done by the miner to create a verifiable image of the physical diamond and produce its ‘digital identity. Before this point, a diamond would have been in the ground for billions of years, so it needs to be introduced to the world carefully and reliably!

When a child is born, for example, they receive a birth certificate. A similar thing happens in the next stage of the process. A stone receives a Birth Registration ID containing a 3D model of its rough shape, identifying data, and country of origin, which is added to Sarine’s cloud-based system. Later, there’s rough diamond mapping and cut planning. The Sarine website says: “Just like a human fingerprint, every rough diamond has unique characteristics that can be determined using Sarine’s advanced diamond mapping technology. For instance, Sarine Galaxy® imaging scans the rough diamond to reveal its internal birthmarks, DiaExpert® maps the diamond’s external surface, and Sarine Advisor® software analyses the rough diamond to explore the polished diamond’s aesthetic and financial value potential.”

The Sarine Diamond Journey provides diamond buyers with detailed information about their unique diamond

I like the way this stage in the Diamond Journey™ allows you to step inside the mind of a diamond-cutter and see precisely how a polished stone emerges from rough and why a particular shape or carat weight yield was chosen based on internal inclusions or crystal shape. Once polishing is complete, the grading process that is true to Sarine’s tech-savvy is done via artificial intelligence. Armed with all this digital data, your next diamond purchase could come with a complete report as well as assurances that it’s natural (especially as you will know exactly where in the world it was mined). David continues: “Everything in a Diamond Journey™ report is based on verifiable data, which adds value to a diamond purchase and offers complete peace of mind. If you know where your diamond came from, you can be assured of its natural origin.”

This level of traceability and transparency also has benefits for the diamond industry, namely helping it to banish lingering question marks around its ethics and social responsibility credentials.

WORDS

Katerina Perez is a jewellery insider, journalist and brand consultant with more than 15 years’ experience in the jewellery sector. Paris-based, Katerina has worked as a freelance journalist and content editor since 2011, writing articles for international publications. To share her jewellery knowledge and expertise, Katerina founded this website and launched her @katerina_perez Instagram in 2013.

Related Articles

Latest Stories

Add articles and images to your favourites. Just

Century of Splendour:Louis Vuitton Awakened Hands, Awakened Minds Chapter II

Creative Director Francesca Amfitheatrof offers her unique interpretation of a pivotal period in France’s history, marked by the French Revolution, the Napoleonic era, and the rise of industrialism

Jewels Katerina Perez Loves

Continue Reading

Writing Adventures:Co-Authoring the Book

Paraiba: The Legacy of a Color

Brand Focus: Louis Vuitton

Jewellery Insights straight to your inbox